Intralogistics

Intralogistics systems play an important role in the automated in-plant transport of materials in factories, distribution centers, parcel services, warehouses, airports, hospitals, and others. These systems increase efficiency, quality, sustainability, and traceability of material flow processes, while reducing waste and inventory buffers. Without them, modern high performance facilities could not function. Electrification components are needed for intralogistic equipment as Automated Guided Vehicles ( AGV), Electric Monorail Systems ( EMS), electric pallet conveyors, rail guided vehicles (RGV), transfer cars, and baggage handling systems, as well as sorters, automated storage and retrieval systems (AS/RS, stacker cranes) and shuttle systems.

Intralogistic systems must be available on demand. If part of the system goes down, processes before and after will stop and the entire facility could shut down. Also, any required maintenance must be done quickly and easily. Energy and data transmission components must adapt to high performance systems, often with complex layouts and operating at high speeds and acceleration. At the same time, they must provide maximum energy efficiency at an acceptable cost. Some systems must meet special technical challenges, such as “clean room” and food processing environments, refrigerated storage, or impure production lines.

Conductix-Wampfler has extensive experience working with intralogistics system OEMs worldwide. From our large product portfolio, we can recommend the optimum solution for individual applications across many different industries without bias towards single technology. With our global presence and local support, we partner closely with OEMs and end-user customers for both small and large scale projects, striving for technical optimization with minimum complexity. Our continuous research & development efforts are geared towards new solutions and continuous improvements of products for this industry.

Inductive Power Transfer (IPT) – powers systems such as AGVs and baggage handling systems. New generations of IPT with state-of-the-art features keep pace with our customers needs.

Conductor Rails – power Electrified Monorail Systems ( EMS), Rail Guided Vehicles (RGV), and baggage handling systems. The SinglePowerLine 0812 and MultiLine 0831, combined with ProShell are ideal for AS/RS stacker cranes. MultiLine 0835 and MultiLine 0365 are the perfect match to power shuttle systems. PEplus for conductor rails works well for electric conveyors of all types, providing safety and simplicity.

Spring-Driven and Motor-Driven Reels – manage cables used to power transfer cars and other moving equipment.

Rubber and Cellular Buffers – are well suited to absorbing energy from machine element impacts.

Jay Radio Remote Controls – offer a safe way of operating or monitoring machines from a distance. The comprehensive range of industrial and safety radio remote controls offers countless solutions to adapt to an extensive number of intralogistic applications.

-

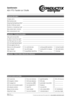

Handhängebahn mit hydropneumatischer Drehscheibe und Hubstation im Lackier- und Montagebereich eines Fahrzeugkabinenherstellers

Referenzbericht

[REF0400-0023-D]

Handhängebahn mit hydropneumatischer Drehscheibe und Hubstation im Lackier- und Montagebereich eines Fahrzeugkabinenherstellers

Anlagenbeschreibung

Handhängebahn mit hydropneumatischer Drehscheibe und Hubstation im Lackier- und Montagebereich eines Fahrzeugkabinenherstellers

Land

Frankreich

Ort

Quëdypre

Vertretung

Conductix-Wampfler [F]

Betreiber

TIM

Technische Anforderung[en]

Transport von Fahrzeugkabinen [bis 1.000 kg] durch den Lackier- und Montagebereich

Produkt[e]

- C-80 Schiene

- Hubstation

- Manuelle Drehweiche

Systemverlauf

Kurvig | Flächenabdeckung: 1.200 m2

Zusatzinformation[en]

Hydropneumatische Drehscheibe

- 1.000 kg

- 360°

Relevant Products

Manuell - C-Schiene

Additional information

Für den innerbetrieblichen Transport bietet Conductix-Wampfler, in Form von Baukastensystemen, individuell angepasste Förderanlagen, die einen optimalen Materialfluss ermöglichen. Verschiedene Zusatzkomponenten, wie Weichen, Bogen, usw., ermöglichen es, komplexe Bahnverläufe zu realisieren. Durch das Baukastensystem und den einfachen Aufbau ist es möglich, eine Handhängebahn für viele Anwendungen zu planen und einzusetzen.

Product data

Die Vorteile einer Handhängebahn sind:

- Niedrige Investitionskosten

- Reduzierung innerbetrieblicher Transportzeiten

- Gesteigerte Produktivität

- Arbeitserleichterung für den Werker

- Produktbezogene Auslegung

- Erweiterung der Anlage ist jederzeit möglich

- Individueller Ausbau durch Sonderkonstruktionen

- Flexible Anpassung an geänderte Produktionsbedingungen

- Einfache Planung durch übersichtlich strukturiertes Baukastensystem

Beispiel-Handhängebahnanlage

- Schienenhalter

- Schienenverbinder

- Bahnverlauf [Fixlängen der C-Schienen 6m] Verschnitt einkalkulieren

- Endanschlag mit Sicherungsschraube

- Ausfahrsicherung für das Verschiebegut während des Verfahrens

- Schleppkettenförderer - Antriebsstation

- Schleppkettenförderer - Spannstation

- Verriegelung auf der Kranbrücke montiert

- Fangstück auf den Stichbahnen montiert

Downloads

Conductix-Wampfler GmbH

Merkezi Almanya Türkiye Şubesi

Istanbul

İMES Sanayi Sitesi

C-308 Sokak No:19

Dudullu OSB/Ümraniye

Turkey

Phone: +90 216 511 58 64

www.conductix.com.tr

info.tr@conductix.com

- 2 more clicks for privacy: By clicking here, the button becomes active and you can send your recommendation to Facebook. With the activation data will be transmitted to third parties.mit Facebook verbunden

- 2 more clicks for privacy: By clicking here, the button becomes active and you can send your recommendation to Twitter. With the activation data will be transmitted to third parties.nicht mit Twitter verbunden

![Transport von Fahrzeugkabinen [bis 1.000 kg] durch den Lackier- und Montagebereich Handhängebahn mit hydropneumatischer Drehscheibe und Hubstation im Lackier- und Montagebereich eines Fahrzeugkabinenherstellers](https://conductix-com-tr-live.cxw-development.com/sites/default/files/styles/teaser-image/public/Pic_1_web_105_1330_1.jpg?itok=whkzCUEP)

![Transport von Fahrzeugkabinen [bis 1.000 kg] durch den Lackier- und Montagebereich Handhängebahn mit hydropneumatischer Drehscheibe und Hubstation im Lackier- und Montagebereich eines Fahrzeugkabinenherstellers](https://conductix-com-tr-live.cxw-development.com/sites/default/files/styles/teaser-image/public/Pic_2_web_105_1331_1.jpg?itok=mNRdNej8)

![Transport von Fahrzeugkabinen [bis 1.000 kg] durch den Lackier- und Montagebereich Handhängebahn mit hydropneumatischer Drehscheibe und Hubstation im Lackier- und Montagebereich eines Fahrzeugkabinenherstellers](https://conductix-com-tr-live.cxw-development.com/sites/default/files/styles/teaser-image/public/Pic_3_web_105_1332_1.jpg?itok=j2RUrUgr)